A process tailored to your needs

Parklane360

It’s our service delivery model—and more. Parklane360 is a philosophy that’s helped us build a reputation for innovation and service excellence over a nearly 30-year company history. It’s about remaining flexible and adaptive, embracing seemingly impossible challenges and never stepping away until the job is done right.

We minimize complexity

Parklane designs, manufactures and installs custom noise and vibration mitigation systems for a full range of commercial and industrial applications. Learn more about our project management systems.

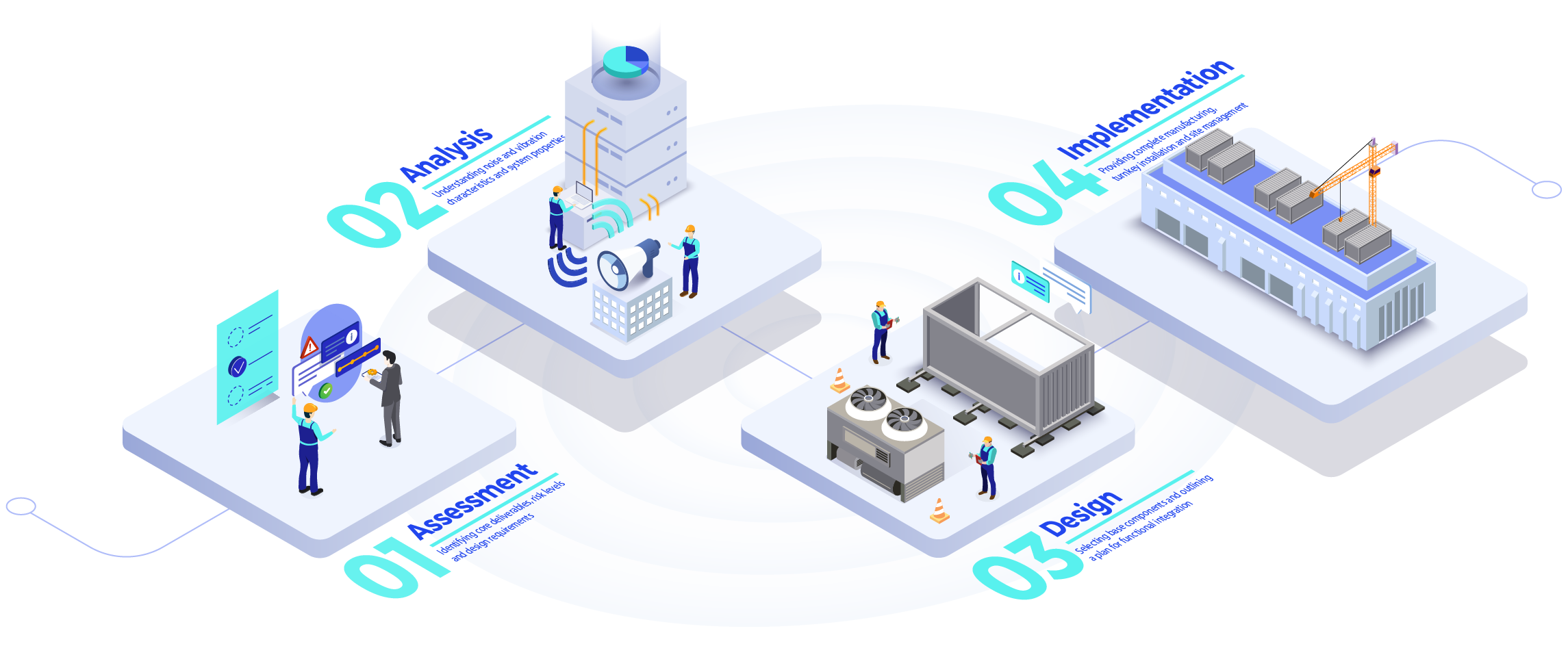

Assessment

Identifying core deliverables, risk levels and design requirements

Design

Selecting base components and outlining a plan for functional integration

Analysis

Understanding noise and vibration characteristics and system properties

Implementation

Providing complete manufacturing, turnkey installation and site management

Understanding noise/vibration characteristics, system properties and site constraints

1 of 4Providing complete manufacturing, turnkey installation and onsite management

2 of 4Work with project stakeholders to identify core deliverables, risk levels and design requirements

3 of 4Selecting base components and outlining a plan for functional integration

4 of 4Scope Evaluation

Detailed project management

At the outset of every engagement, we assign a dedicated project manager—an engineer with technical understanding and installation expertise—as your single point of contact. Our in-house engineering and project-management departments assess and analyze noise and vibration control issues, with a focus on everything from constructability constraints to installation logistics.

Budget Control

Our comprehensive process is designed to minimize the added costs that can go overlooked as we progress into the implementation phase.

Project Certainty

Our in-depth analysis ensures that unforeseen risks are discovered and project requirements are accurately scoped out to avoid costly oversights.

Integrated noise control & VIRS solutions

Strategy

Our team utilizes the empirical data collected during the assessment phase to develop a customized solution to your noise or vibration challenge. Along the way, we look beyond the obvious concerns and develop mitigation strategies that account for critical considerations such as engineering requirements and building aesthetics.

Rapid Response

An effective approach enables our team to strategize and address a noise issue without delay.

Effective Communications

Our information sharing processes help ensure accuracy and on-time project delivery without errors.

Flexible to meet your needs

Adaptive Systems

We design, manufacture and install noise and vibration mitigation componentry with careful attention to all relevant site-specific details. Our solutions can be individually designed to seamlessly integrate with any on-site condition. That means you have total flexibility to customize the final output parameters for your custom solution.

Reliable Manufacturing

We manufacture customized components in-house to your team’s exact technical specifications, avoiding wasted time spent performing on-site rework.

Peak Performance

Our approach cuts the risk of compromised performance or functionality, while delivering effective component connection and structural support.

Customized Delivery

Because no two projects are the same

Our flexibility and adaptability allow us to fit into a project as needed. That often means tailoring our offering to align with existing service-level agreements and client resources. For example, we’ll often be called on to supply componentry to a third-party contractor who will then manage its installation. At that point we leverage our engineering expertise and provide assistance to guarantee the component’s full constructability. That’s only one of the many ways that Parklane services can be customized to suit your requirements

Cost Control

Our detailed product delivery process allows us to conduct a clear cost-risk assessment to ensure your project is completed on time and on budget.

Effective asset allocation

Efficiency is the key to any project’s success. Full customization minimizes the labour required to deliver your noise or vibration mitigation solution.

Comprehensive Solutions

Products and Services

As the distributor and implementation specialist for the Mason Industries VIRS product line in Ontario, we also supply the components to meet all of your vibration-control needs, along with the technical product and engineering expertise to ensure seamless integration and ongoing maintenance.

Agile Engineering

We not only analyze the source of sound emissions or VIRS issues in collaboration with our acoustical consultant partners, but our team conceives the agile engineering solutions to mitigate those sources.

Turn-Key Engineering

We leverage turnkey implementation and site management processes to deploy customized solutions in a way that minimizes any impact on facility operations, before manufacturing the required mitigation components.

SCOTT CAMPBELL | GILLIN ENGINEERING & CONSTRUCTION LTD. | PARTNER

Don’t let mechanical noise or VIRS issues disrupt your business

Contact a member of our team now to discuss how we can help address your commercial or industrial acoustic or vibration challenge.